Recirculating aquaculture systems (RAS)

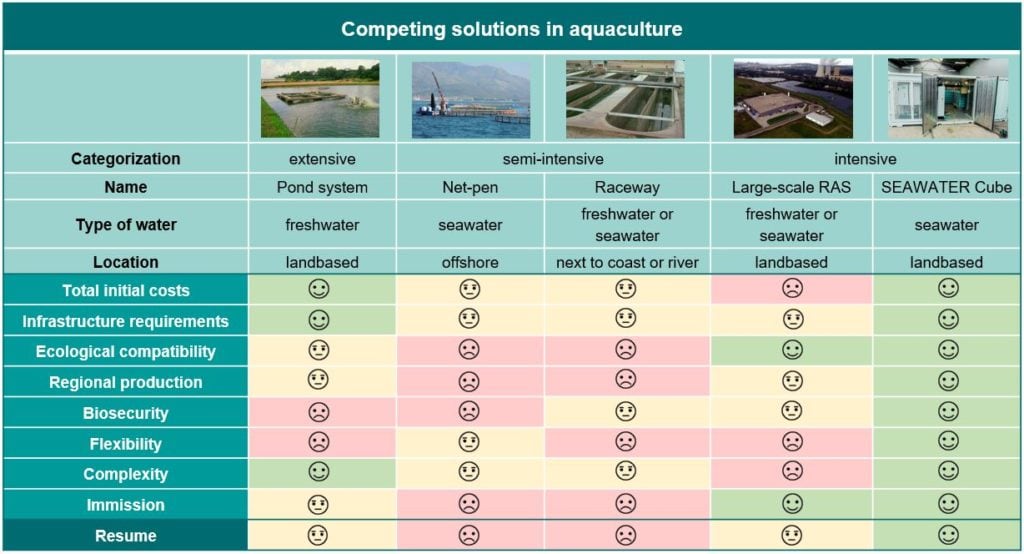

The cultivation of fish on land has been greatly optimized over the past centuries. In particular, the closed recirculating aquaculture system (RAS) has now established itself alongside traditional aquaculture methods such as pond systems, net cages and flow-through systems. In order to get a concrete overview of the differences between these methods, the characteristics of technological recirculating aquaculture systems are compared with traditional breeding methods. In addition, the SEAWATER Cube is used to explain the construction of an innovative closed recirculation system in detail in the individual process steps.

Traditional aquaculture vs. high-technological recirculation systems

If you compare extensive or semi-intensive methods such as pond systems, net cages and flow-through systems with closed recirculation systems, the differences quickly become clear with regard to the following overview. From an ecological point of view, the RAS have a clear advantage and also with regard to the regionality of production and the reduction of emissions these systems can score points.

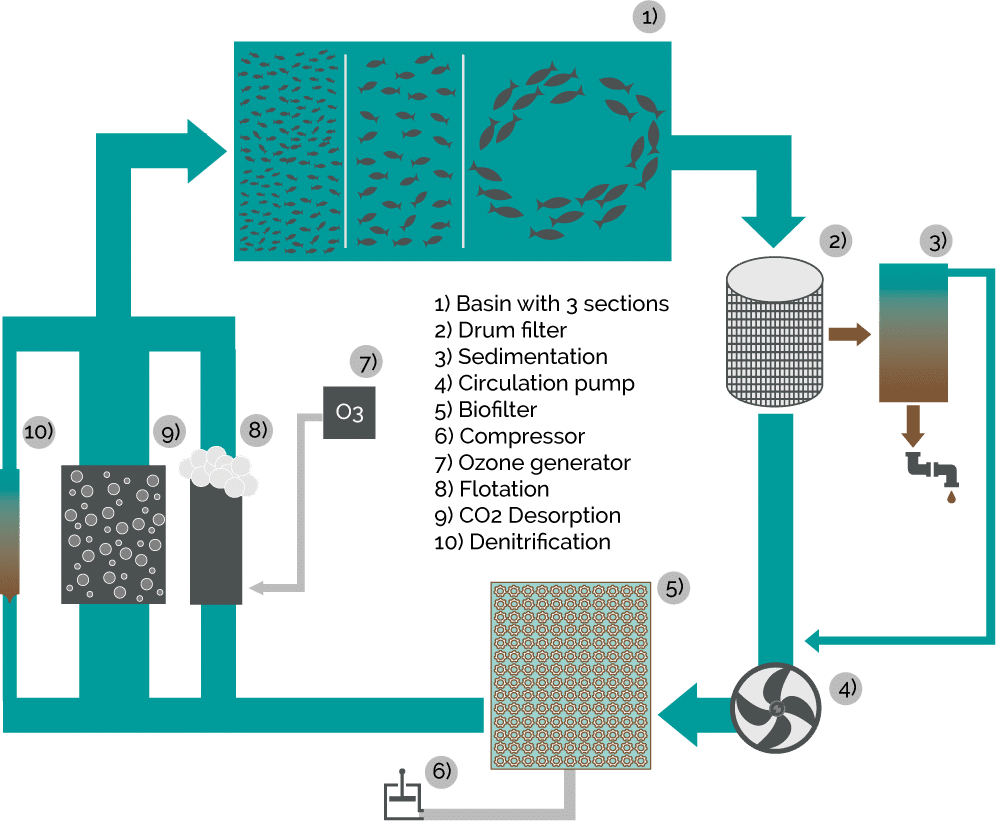

Design of a closed recirculation system using the example of the SEAWATER Cube

The SEAWATER circuit, as a closed circuit for rearing fish, is composed of 10 essential components for water treatment. The fish bearing tank, the drum filter, the circulation pump and the biofilter with aeration by the compressor are located in the main circuit. Also, the skimmer with addition of ozone by the ozone generator, the CO2 desorption and the denitrification are in the main circuit, but they are only charged with a part of the water flow. The sedimentation is located in a bypass of the drum filter and the fish bearing tank.

- The fish bearing tank is completely filled with water and serves as habitat for the animals. Fish feed and oxygen are put into it. In addition, the excrements of the fish (feces, CO2, ammonia or ammonium) are transported by the strong current of the water to the first component of the water treatment. Relevant and measurable parameters are among others the salinity (in saltwater aquaculture), temperature, pH-value and redox potential as well as oxygen content.

- The drum filter is used to discharge solids and particles generally larger than 40µm (depending on the mesh size of the filter gauze)

- The particle-contaminated backwash water is led into the sedimentation for water reclamation. There the particles settle on the bottom. This formed sludge is specifically removed from the system, whereas the clarified water in the upper part of the sedimentation is returned to the system.

- The circulation pump transports the water of the system from the pump well, with the drum filter inside, into the water treatment components and thus generates the necessary flow for the water treatment.

- The biofilter uses the biological process of nitrification to convert the ammonia or ammonium excreted by the fish first to nitrite and then to nitrate. This task is performed by autotrophic, aerobic bacteria, which adhere to plastic carriers (carriers or filter pellets) by forming a biofilm.

- This former process requires oxygen, which is transported by the compressor into the filter component.

- The ozone generator supports the process of foam formation in the subsequent step and promotes the detachment of proteins from particle surfaces.

- The skimmer is a physically working device, also called „flotation“ or „protein skimmer“. In this process step, surface-active protein compounds are adhered to the air bubbles introduced in a countercurrent process. This produces a foam formation. The foam is then discharged with the ampholytic substances, viruses and particles (e.g. bacteria) adhering to it. In the skimmer all small particles (< 40 µm) are removed from the water which could still pass the drum filter.

- CO2 desorption is a degassing component to remove the carbon dioxide excreted by fish and bacteria into the water. In addition, the outside air introduced in the CO2 desorption serves to cool the water.

- The anaerobic biofilter, the so-called denitrification, also works with bacteria and corresponding carriers. Denitrification essentially represents the conversion of nitrate to elemental nitrogen (N2) and works only at low oxygen concentrations (approx. < 0.1 mg/L; anaerobic conditions = under oxygen exclusion). The nitrogen is released into the ambient air.

Finally, if you take a look at the different systems, it can be stated that open aquacultures such as pond systems are probably the „ideal“ in the minds of consumers due to their biodiversity. Due to the enormous amount of space required, these breeding methods cannot be used to sustainably increase the population in Germany. The high losses caused by diseases, climatic extremes or fish-eating animals are also problematic.

The decisive advantage of closed recirculation systems is their independence from external influences. Where up to now mainly large-scale plants were state of the art, alternative concepts are slowly developing. The SEAWATER Cube is an example of a modern, compact and standardized plant system. It enables the production of upscale edible fish, which small to medium-sized companies can offer for sale regionally. In addition to the small space requirement, no major construction and installation work is required for the commissioning of the plant. With innovative components, we always ensure a very good water quality in the plant and can thus greatly reduce the occurrence of diseases. In the SEAWATER Cube, the use of antibiotics is completely avoided and the important bacterial cultures in the biological filters are spared. Furthermore, with this system we create the possibility of a transparent production, which therefore offers the consumer more transparency and creates a proximity to the product.

Aquaculture is the fastest-growing area of food production. Investing in sustainable fish farming methods is worthwhile, as this is the only way to conserve the world’s oceans and make a decisive contribution to protecting natural stocks.

References:

— Badiola, M.; Mendiola, D.; Bostock, J.: Recirculating Aquaculture Systems (RAS) analysis: Main issues on management and future challenges. Elsevier B.V., 2012.

— Lekang, O.-I.: Aquaculture Engineering. Second Edition, John Wiley & Sons, Ltd., 2013.

— Martins, C. I. M.; Eding, E. H.; Verdegem, M. C. J.; Heinsbroek. T. N. et al: New developments in recirculating aquaculture systems in Europe: A perspective on environmental sustainability. Aquacultural Engineering, Elsevier B.V., 2010.

— Orellana, J.; Waller, U.; Wecker, B.: Culture of yellowtail kingfish (Seriola lalandi) in a marine recirculating aquaculture system (RAS) with artificial seawater. Elsevier B.V., 2013.

— Steinbach, C.: Entwicklung eines Substrates für Fließbett-Denitrifikationsstufen in Fluidkreisläufen der Marikultur. Masterthesis, Hochschule für Technik und Wirtschaft des Saarlandes, 2014.

— Schaar, S.: Auslegung eines denitrifizierenden Biofilters in einer geschlossenen Kreislaufanlage für Wolfsbarsche. Bachelorthesis, 2019.

— http://orgprints.org/32165/1/32165–15OE026-naturland-bergleiter-2017-kreislaufanlagen-aquakultur.pdf, aufgerufen am 02.10.2019

— Stavrakidis-Zachou, O.; Ernst, A.; Steinbach, C.; Wagner, K.; Waller, U.: Development of denitrification in semi-automated moving bed biofilm reactors operated in a marine recirculating aquaculture system. Springer Nature Switzerland, 2019.

— van Rijn, J.: Waste treatment in recirculating aquaculture systems. Aquacultural Engineering, Elsevier B.V., 2012.