STANDARDIZED URBAN FISH FARMING

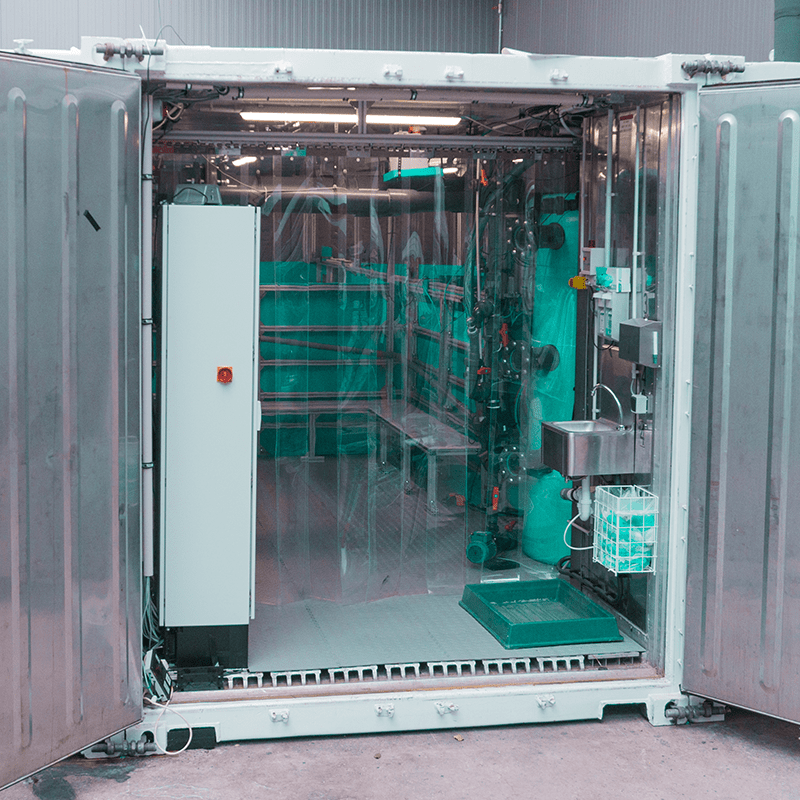

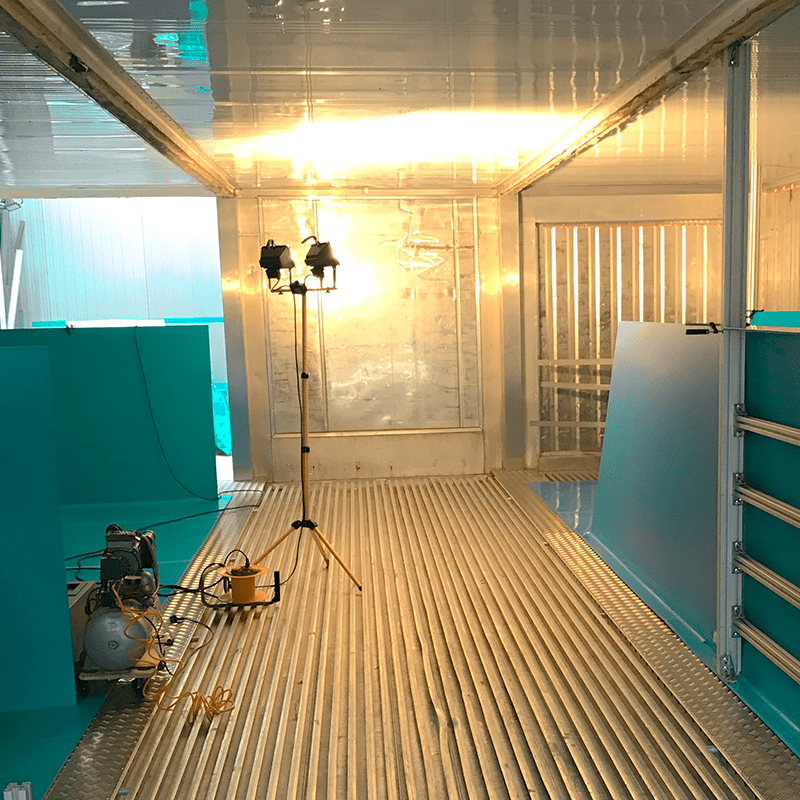

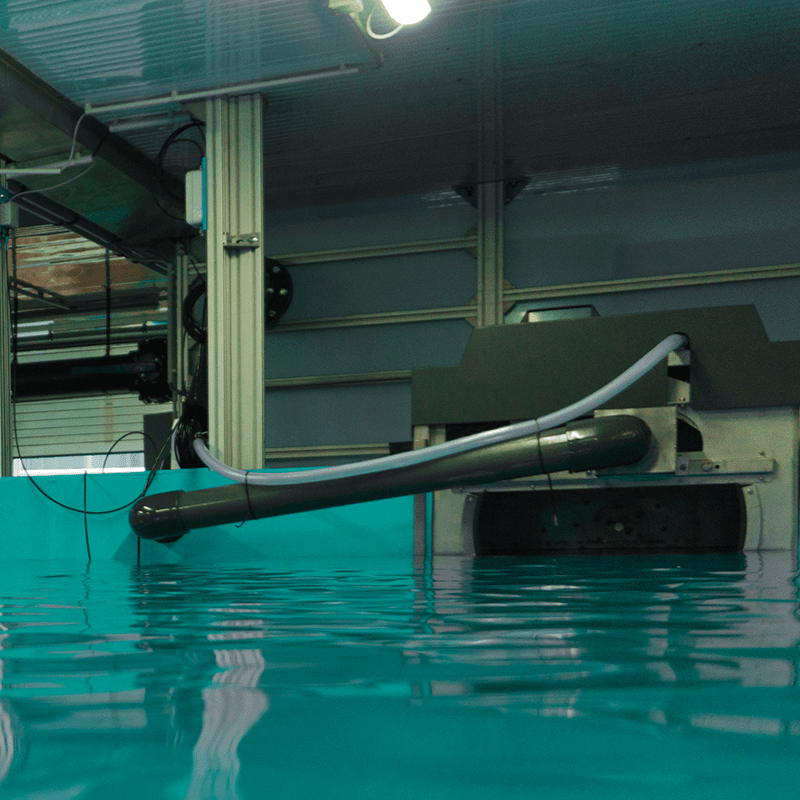

The SEAWATER Cube is the world’s first compact, plug-and-play aquaculture system. The technology is housed in four shipping containers on a floor space of only around 250 m² (including manoeuvring area). This makes the system perfectly suitable for food production in urban areas where space is limited. We pre-assemble the Cube in series production and connect it at the customers site in just a few steps to form an operational unit. Mechanical and biological filters recycle 99% of the water within the system and remove any waste without leaving residues. This helps conserving natural resources and the fish growing up under the best conditions. Our Cube enables an annual production of around 7.8 tons of fish.

Fix investment

Thanks to the standardization, we can offer the system at a fixed price. If necessary, there are also costs for processing and the first operating resources.

Predictable delivery

The production time of a system is currently approx. 4–6 months due to the lead times at our suppliers. In our factory, we can manufacture two systems in parralel.

Short assembly time

We assemble the system in four units in our headquarter and carry them to the customer for final assembly on site. The system is installed and operational within a few days.

Low space requirements

With its compact design and a footprint of only 250 m², the Cube fits ideal in locations where space is limited. Additionally it is perfectly suited for urban farming concepts as well.

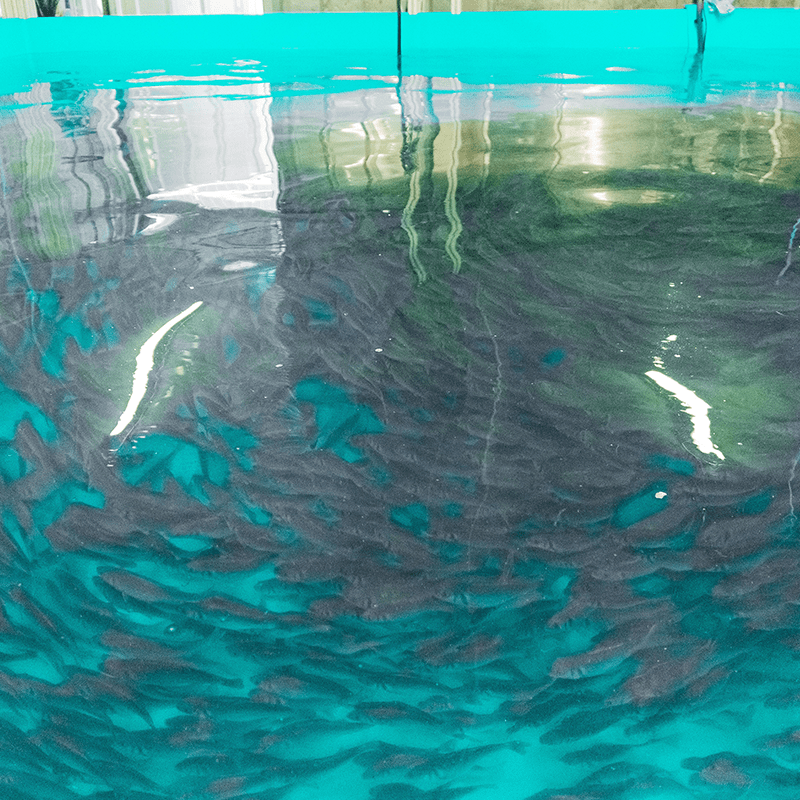

ATTRACTIVE FISH SPECIES

Our farm is specialized for growing saltwater fish. This is technologically more complex than the aquaculture of freshwater fish. With our system, we are among the pioneers in the field of marine, land-based fish farming and see a very large market potential in marine fish. Sea fish is often processed in the gastronomy and due to the tasty meat and the elegant optics, the different types are particularly popular with consumers. For each type of fish, the system has to be set up individually to the appropriate parameters for the animal (e.g. water temperature, salt content, stocking density). It is therefore difficult to give general statements about production quantities, operating costs, etc. across all fish species. We would be happy to discuss specific scenarios in personal with you.

Digitized plant operation

The built-in control software reduces the workload in the production to approx. 8 hours per week. All fish knowledge is stored in the automation so that the operator acts more in a controlling than a regulating manner. For example, the Cube knows when it is time to feed the fishes and how much they need. This information will be given to the feed dispensers and the operator itself only has to fill them up regularly. In addition, all important water parameters are recorded with the help of various sensors and are displayed on the control panel. In case of deviations, the system knows how to counteract. The course of the values can be viewed via graphs. There is also an app for the mobile phone, so that access to the data and control of the system are also possible from home or on the go. In addition, the system can be accessed remotely, so that we can actively support you with questions or problems.

We have listed the most important steps in system operation below.

Monitoring

The daily visual control of the fish stock and the monitoring of the recorded values by the operator are the most important tasks in the plant operation.

Refilling

In addition, all important consumables such as feed, salt or chemical substrates must be refilled and oxygen bundles have to be replaced at regular intervals.

Cleaning

The daily care and maintenance of the system is also an important task. This ensures hygiene and functionality and the production is always presentable to guests.

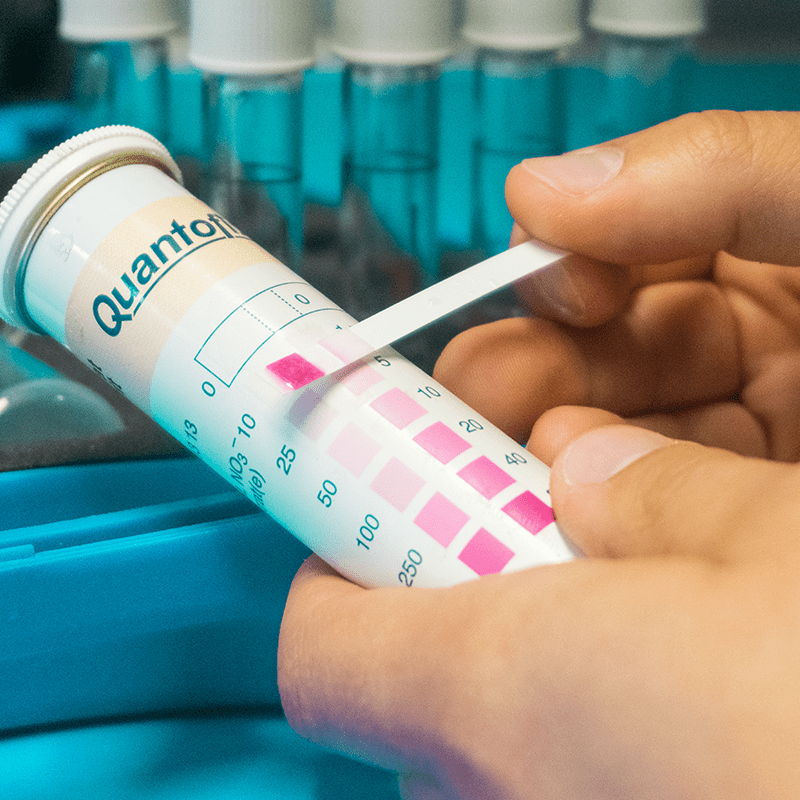

Analyzing

Some substances cannot be detected with sensors yet, but in high concentrations they quickly become critical for the animals. Therefore, weekly water analyzes with strip tests have to be made.

CONTINUOUS PRODUCTION

Continuous production is achieved through our cohort model. The production tank is divided into basin areas of different sizes or age groups (the cohorts). The areas are separated by nets. The fishes have their market size at around 350 to 400 grams and reach this after eight to twelve months. From this results a stocking plan in which the animals spend four months in each cohort. In contrast to the „in-and-out process“, this means that the entire production volume does not have to be sold at once, but can be fished permanently according to demand. If the basin of the market-ready fish is empty, the following age groups are each moved one section further and the first area is re-stocked with young fish (seedlings).

ALL IN ONE: HARDWARE, SOFTWARE & SUPPORT

After the plant has been commissioned, the real work begins. It is important for us not to leave the customer alone, but to do our part to ensure that our operators are successful. In order to ensure smooth operations, we conclude a service contract when selling the system. This includes regular technical maintenance of critical system components, the replacement of certain wear parts as well as a 24-hour availability by phone and remote maintenance in the case of technical challenges.

TECHNICAL DATA

| Production 7,8 t raw fish | year |

Volume of water 70 m³ |

| Footprint 100 m² |

Water exchange 500 l | day (< 1%) |

| Cube Dimensions 12,20 x 7,20 m |

∅ Stocking density 65 kg | m³ |

| Power consumption 48.000 kWh | year |

Amount seelings 21.000 pieces |

| Workload 8 hours | week |

∅ Feed amount 25 kg | day |

BUSINESS ECONOMICS

Basically, fish farming in a closed system, taking animal welfare and the environment into account, is more cost-intensive than aquaculture in the wild nature. The operation of a recirculation aquaculture plant makes sense if the project pays off. Even with a standardized system, the return on an aquaculture business depends on various individual factors. Among other things, the location and the existing infrastructure, the legal requirements and funding opportunities in the respective federal state as well as the electricity price and wage costs influence the profitability calculation.