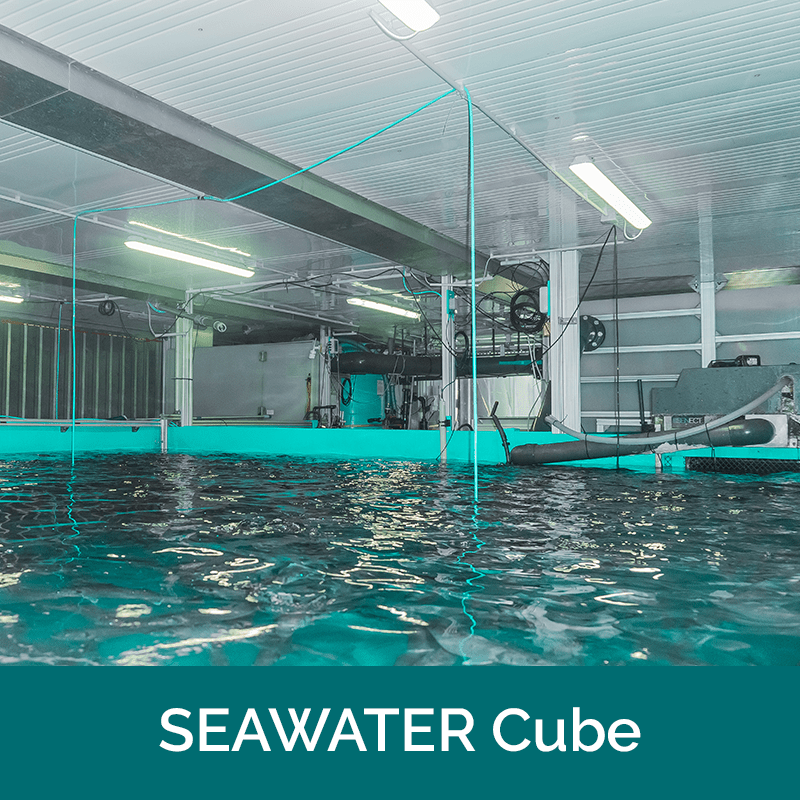

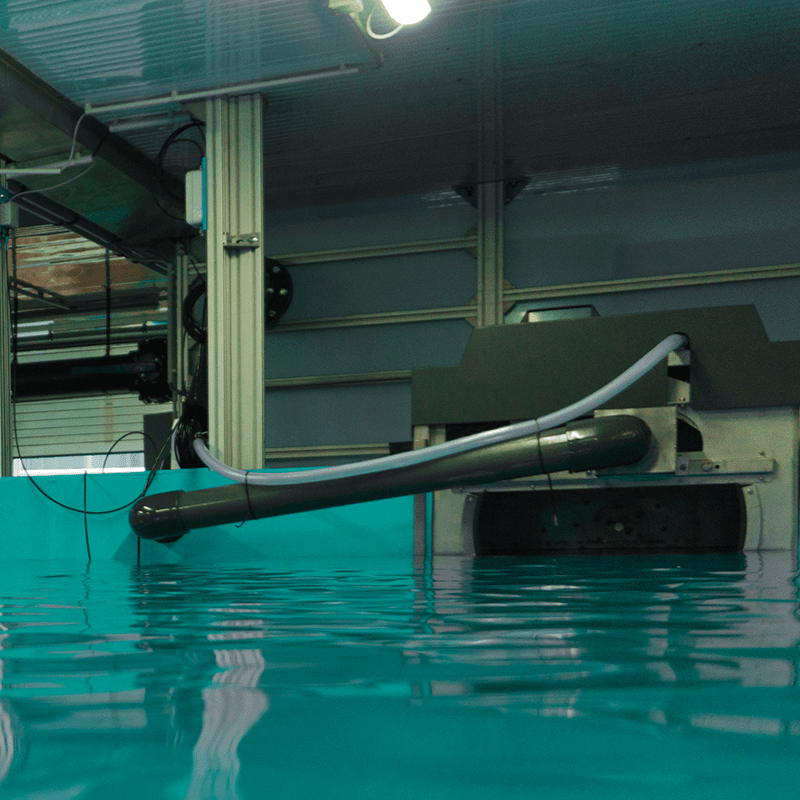

SEAWATER CIRCUIT

Replacing large amounts of process water is cost-intensive and wastes valuable resources. In a saltwater aquaculture, the aim is therefore to achieve the lowest possible water exchange. The SEAWATER circuit consists of various mechanical filter units as well as our patented biofilters. These remove completely all feed residues and animal excrements from the tank. The animals can grow up in clear water under optimal conditions and without stress. This enables the best product quality. The special thing about our technology is that we combine natural and engineering sciences. All components in the system are precisely designed for each other in terms of process technology and respect the strict requirements that the animals place on water treatment.

Filters

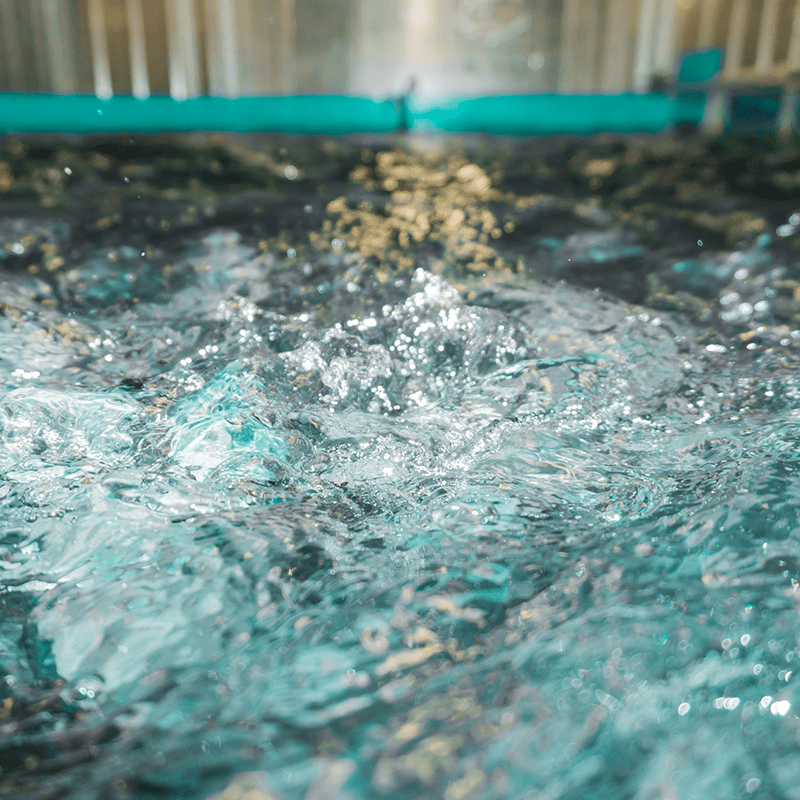

We combine several mechanical and biological filters in our circuit. Every drop of water in the basin goes through all filters three times an hour.

Water exchange

By combining mechanical and biological filter units, 99% of the water in the Cube is cleaned – so there is only a consumption of 500 liters per day.

Circular flow

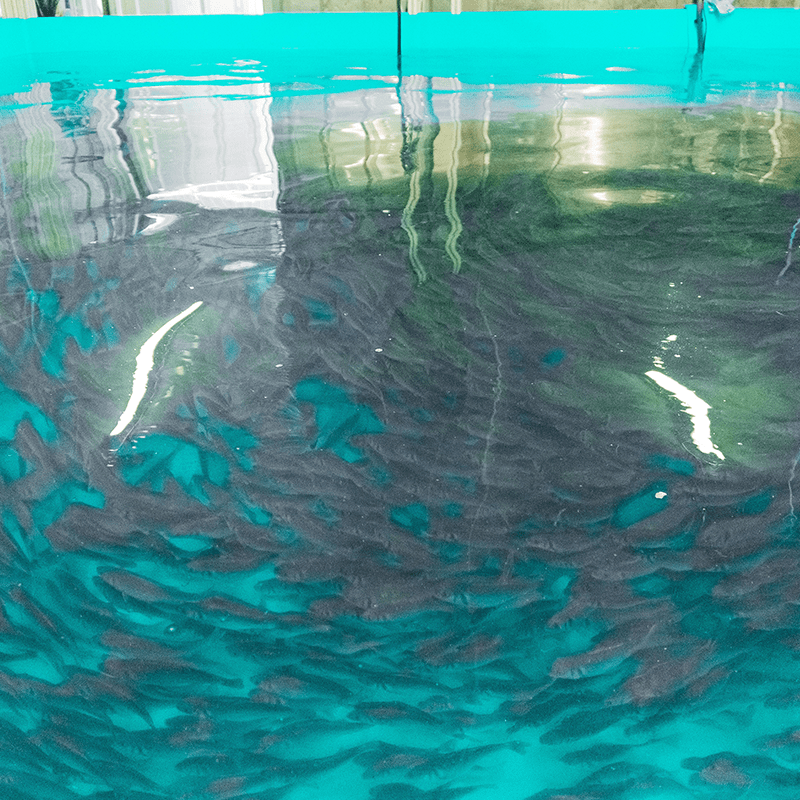

Using powerful pumps and airlifts, we generate a circular flow in the system, which provides the fish with ideal conditions to develop their natural swarming behavior.

Salt water

The basis for the SEAWATER is normal tap water. This is salted with a special mineral mixture that is similiar to natural water from the sea.

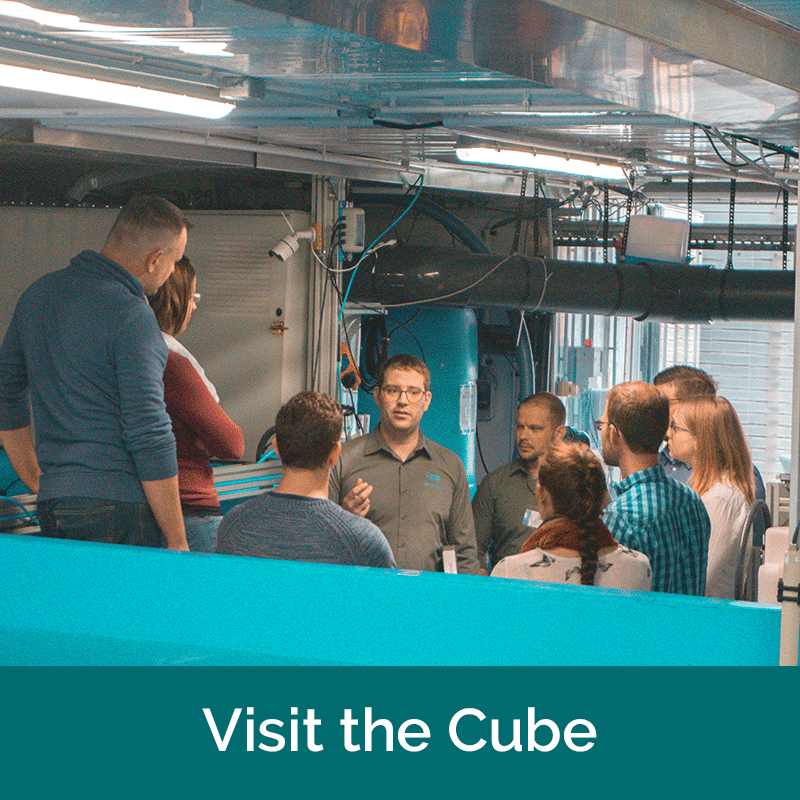

SEA FISH FAR AWAY FROM THE SEA

The SEAWATER Cube as a recirculating aquaculture system is characterized by its location independence. The system runs far away from natural waters and therefore has no interactions with the environment. Negative influences on the seas, for example by net cages from fish droppings, feed excesses and animal carcasses, are completely avoided. In addition, meteorological events (e.g. El Niño) or industrial pollution (microplastics, heavy oil, heavy metals) do not threat the animals. Recirculating systems enable controlled rearing and create transparency with regard to the origin and the ingredients of fish products.

INTELLIGENT SELF-REGULATION

The switch cabinet is the heart of our system. The programmable logic controller („PLC“ for short) is installed here, in which the species-specific fish knowledge is stored. In addition, the data from all actuators, sensors and subsystems run together in the PLC. Various functions are programmed into the software. Thus, the software controls all processes in the system fully automatically within specified value ranges. This reduces the workload for the operator and increases production reliability significantly. The automation also saves all recorded data in the cloud. This is used for regular analysis and optimization of the production processes.

DENITRIFICATION AS WATER FILTRATION

Denitrification as water filtration in the absence of oxygen removes toxic nitrogen compounds from a partially closed or closed aquaculture plant. During this process, nitrate (NO3) is broken down from the water in the system with the help of special bacteria. The denitrification process has the following advantages: Since no toxic nitrate accumulates in the basin, the water change rate and thus water consumption can be reduced to 1% per day. In addition, the fish grow up in an unpolluted environment and animal welfare is permanently guaranteed. The fully automated SEAWATER denitrification reduces the daily workload in the plant.