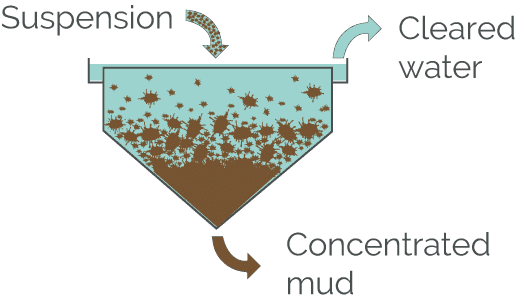

Sedimentation in detail

The term „sedimentation“ is well known from wastewater treatment plant technology. In a sedimentation, e.g. a settling tank, the solids present in the water sink to the bottom due to their density (higher than water). In the upper part of the sedimentation, clear water collects (free from solids), which can be reused or returned to the original process. The sediment, an aqueous sludge, can be collected and removed at the bottom of the sedimentation. A sedimentation aims at water purification or recovery.

There are two sources of solid particles in an aquaculture circuit: 1. uneaten feed pellets (feeding) and 2. the excrements of the fish (feces).

Both the feed pellets and the excrements still contain sufficient nutrients to allow bacteria to multiply. However, this effect is undesirable in an aquaculture plant, as too many of the wrong bacteria can affect the health of the fish. Therefore, in aquaculture, the solids must be removed from the system quickly and efficiently. In recirculation systems, the drum filter collects particles up to a certain size through its filter gauze, a very fine-meshed filter net (approx. 40µm mesh size). The drum filter needs regular flushing of the filter net in order to guarantee its function permanently. This rinsing water, which is contaminated with the collected solid particles, is introduced into a sedimentation system in order to recycle it and reduce the water consumption of the plant.

In the SEAWATER Cube the sedimentation is a container with a distinctive cone. The inlet is via a so-called „Dortmundbrunnen“. In this the water is directed vertically upwards. This creates special flow conditions in which the particles contained in the inflow water have more time to gather (coagulate). As a result, even particles that are too light to sink on their own can coalesce into larger particles and then sink to the bottom due to their higher weight. A sludge is then formed there.

In summary, sedimentation serves to recover rinse water by separating solids from the rinse water of the drum filter by sedimentation. The clarified water can be fed back into the main cycle, saving a considerable amount of water. In total, the SEAWATER cycle achieves to purify 99% of the water in the plant itself. Only 1% of the water volume (~ 500 L) is lost per day through evaporation or flushing and has to be replaced. The filter units thus make a decisive contribution to the sustainability of our plant.

References:

— https://www.leiblein.de/produkte/schraegklaerer.html, 05.05.2020

— https://www.stadtentwaesserung-dresden.de/wasserwelten/wasser-wissen/dresdens-virtuelle-klaeranlage/, 05.05.2020

— Image source: SEAWATER Cubes