First step in water treatment: The drum filter

Almost everyone has done this at least once in their own four walls: For example, you use a sieve and water and simply rinse the dirt away, leaving only the clean salad at the end. This is a type of mechanical cleaning that almost everyone uses regularly. In order to achieve a similar effect in a recirculating aquaculture system (RAS), a comparable filter option is used in a figurative sense: the drum filter, a cylindrical drum covered with a fine-mesh filter net. More than half of the drum is under water, so that the process water from the production basin with all its particles can flow unhindered into the drum at the open front side. The drum’s filter net allows the water to pass through, but at the same time retains the coarse particles – in comparison to our example with the lettuce sieve, the exact opposite way.

Which solids are removed by the drum filter?

These particles to be separated are bacterial flakes, unused food and feces (= excretions) from the fish. These particles are undesirable in the water and must therefore be removed. The easiest and cheapest way to do this is to use the drum filter. The stainless steel net, the so-called filter gauze, collects all solids in the SEAWATER Cube that are smaller than 40 µm. The pre-clarified water, which hardly contains any solids after passing through the gauze, collects below the drum filter in the so-called pump sump. From there the water is transported to the other filters via the main pump. This ensures the smooth functioning of the downstream filters.

How does the filter technology work?

By measuring the fill levels in the production tank and in the pump sump, the drum filter detects whether it needs to be cleaned. If the height difference between the basin and the sump is too great, this means that too little water is currently getting through the drum into the sump. This happens when the filter gauze is already covered with too many particles. In this case the drum is rotated. On the one hand, the filter gauze on the top of the drum is rinsed free with a high-pressure pump and water nozzles. On the other hand, fresh, already rinsed gauze reaches the bottom of the water, which is permeable again and can collect new particles. This process is repeated at regular intervals. The dirty rinsing water collected in a channel is directed into the sedimentation. Only after this further clarification process does the water get into the wastewater. It therefore counts as part of the water that is exchanged in the cube every day (1% per day).

As a type of microfiltration, the drum filter is particularly low-energy and reliable due to its pumpless (or almost pressureless) mode of operation. Due to the regular self-cleaning, the backwashing, the work and maintenance effort is also relatively low. If a change in mesh size is required or if the gauze is cracked, changes can be made to the filter quickly and easily. In aquaculture, the drum filter is a common mechanical filter due to its many advantages in handling and is therefore also used in the SEAWATER Cube.

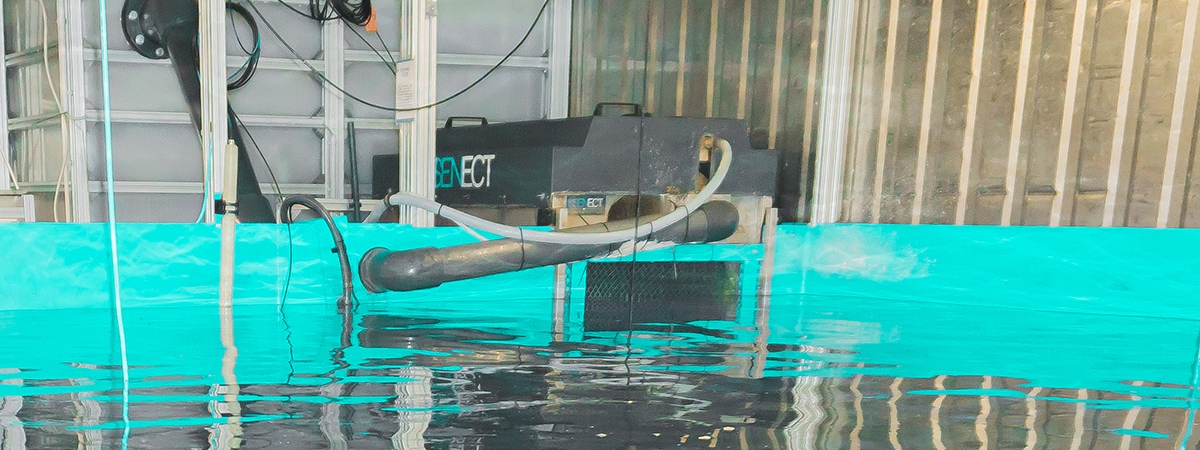

We get our drum filter from the Senect company in Landau.