Cohort model

Already in the Middle Ages, monks divided their carp ponds into sections of different sizes. Even today, the separation of the farmed fish into so-called cohorts is still used. But what is this division actually good for?

The basic idea behind the cohort model is to separate the smaller fish from the larger ones. Especially with predatory fish (carnivores), this prevents the larger fish from snatching away the existing food through physical superiority or even eating the smaller ones.

Today, in the time of ultramodern, technical (closed) aquaculture systems, there are even more reasons for cohort models:

Production reliability: As standard, separation is done by means of round tanks of different sizes. Here, the animals can be separated not only spatially, but mostly also by independently working water circuits. Thus, in case of illness, only one tank with its stock (batch) is affected and must be treated or emergency killed. The remaining batches in other tanks remain undamaged.

Feeding: Both the amount of feed and the size of the feed pellets depend on the size and weight of the animals. Since the fish are divided into cohorts according to size and weight class, they can be fed with the appropriate pellet size in a very precise and resource-saving way.

Availability: A cohort model also ensures continuous production. Among the cohorts, there is always one in which the animals have reached market maturity. At the same time, new autumn fries are already being used in other cohorts, so that a continuous cycle of fishing and restocking is created across all tank areas.

Plant stability: Modern aquaculture plants no longer work only with natural water exchange (e.g. from sea or river) to keep the water clean. Today, filter technologies (e.g. drum filters, biofilters, denitrification, …) are used to remove unused food and excrements of the fish from the water without polluting the natural waters or the environment. These filters are particularly stable and efficient when they have about the same amount of work to do every day. Due to the cohorts and the resulting balance of fish and replenishment, there is always about the same amount of biomass in the plant. This in turn means that the amount of feed per day also fluctuates very little around the average value. The filters are designed in such a way that they optimally and energy-efficiently break down the average amount of excreta and residues.

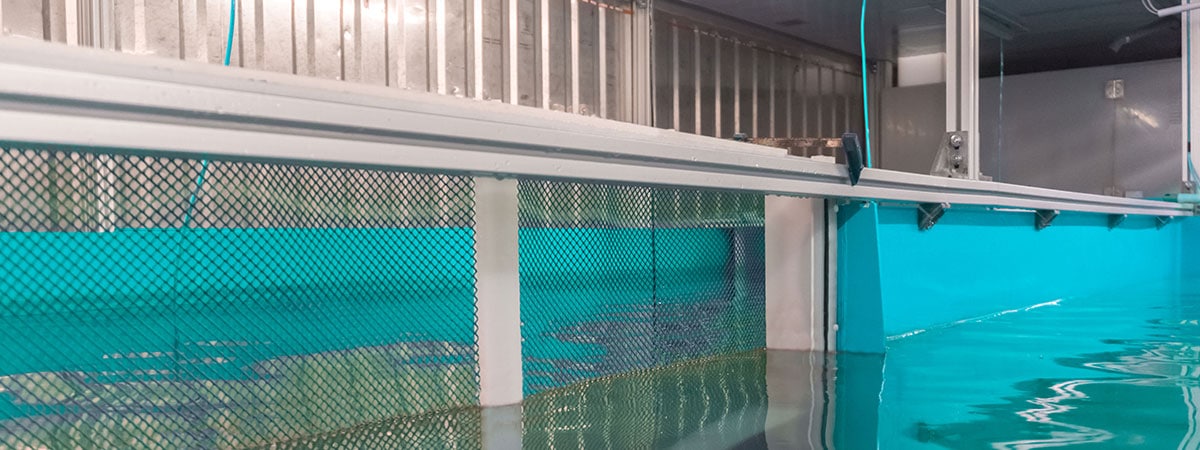

In the SEAWATER Cube we work with a single large tank. Nevertheless, in this three cohorts of different sizes are separated by net constructions. Since the growth of sea bass up to its market weight of about 400 grams takes about 12 months, the animals live in one cohort for 4 months each. After that, they are transferred to the next cohort through a sluice in the net construction without machines or contact.

Further informationen about the SEAWATER Cube

Check out more facts about our system and the technology.

References

— FAO (Food And Agriculture Organisation Of The United Nations), 2016. The State Of World Fisheries and Aquaculture. Rome

— European Inland Fisheries Advisory Commission, 1986

— Wu, R.S.S., 1995. The environmental impact of marine fish culture: Towards a sustainable future. Marine Pollution Bulletin 31, pp.159–66

— Sumari, O., 1982. A report on fish farm effluents in Finnland. Report of the EIFAC Workshop on Fish-Farm Effluents. EIFAC Technical Papers 41, pp.21–27.

— Pillay, T.V.R., 2004. Aquaculture and the environment. Second Edition ed. Oxford: Blackwell Publishing.

— Timmons, M.B. & Ebeling, J.M., 2010. Recirculating Aquaculture. 2nd ed. New York: Cayagua Aqua Ventures.

Image source

Colourbox, ID#9435269